- Pulp Machine

- Paper Coater

- Drying Equipment

- Yankee Hoods

- Hot Air Drying Cabinet

- Air Diverter

- Through Air Dryer (TAD System)

- Paper Machine Hood

- Auxiliary System

- Dust Removal Equipment

- PPCS Pulse Jet Baghouse Dust Collector

- XD Multi-Cyclone Dust Collector

- Wet Dust Collectort

- Combined Electrostatic Precipitatort

- Noise Control Equipment

- Heat Recovery Device

- Centrifugal Fan

- Axial Flow Fan

- Papermaking Workshop Ventilation Equipment

- Air Supply System

- Turnkey Projects

- Pulp Drying Machine and Drying System

- Tissue Paper Making Machine

- Specialty Paper Machine

Pulp Machine

Introduction

Pulp drying machineconverts wood chips or other plant fiber source into a thick fibre board which can be sent to a pape machine for further processing. The paper pulp drying machines are suitable for papermaking industry.

Advantages

1. Pulp drying machine saves construction costs, for the length of drying section can be shorten by more than 50%.

2. It can conveniently adjust horizontal moisture difference.

3. Pulp boards suffer smaller tension, leading to fewer broken paper sheets.

Features

1. Pulp drying machine enjoys low power consumption, high level of reliability and low maintenance cost.

2. The rotor combines hydrodynamic system with mechanical system for dissolving paper pulp.

3. Paper pulp drying machines adopts traditional vertical pulper.

4. Pulp machine can easily separate fibers and minimize fiber loss.

Component of Pulp Drying Machine

1. Twin Wire Forming Section

Twin wire forming section is composed of hydraulic headbox, closed dehydration system, dewatering tank, wire tensioning device, wire rectifier and cleaning device.

2. Press Section

Press section mainly consists of a set of vacuum preloading devices, a set of vacuum pressing devices and a set of high impulse pressing devices. This section is designed based on adequate consideration about the features of pulp drying machine , so that pulp boards have better dehydration.

3. Dryer Section

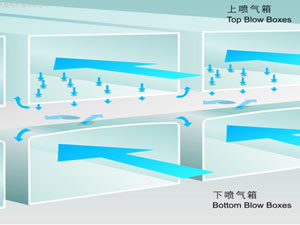

The dehydration of pulp boards is based on floatation non-contact drying principle. The dryer adopts multi-layer arrangement. The number of jet cases and their layout depend on actual production capacity.

Paper webs are dried by hot air from top and bottom jet cases. And these jet cases are separated by air cylinder, bringing a lot of convenience to maintenance and cleaning.

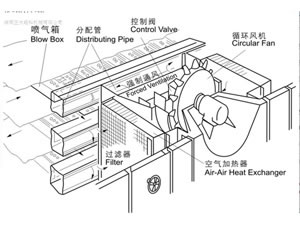

External Hot Air Circulation Process

To maximize use of energy, pulp drying machine applies two-stage heat recovery devices to the external hot air circulation system.

1. The primary gas-gas heat recovery device makes use of hot and humid air ejected from top dryer to warm up fresh air. Later, the fresh air is heated by heater and then sent to bottom dryer.

2. The secondary gas-water heat recovery device heats the process water and heating water by utilizing the residual heat of exhaust gas.

3. The bottom of dryer is equipped with an air supply system, ensuring that pulp boards are cooled down before leaving drying section.

- Paper CoaterBlade coater is a kind of paper coater which is generally applied to the production of BOPP (Biaxially-oriented Polyropylene) packaging tapes. It uses a high-speed coating head which can effectively reduce bubbles. The operating speed of scraper coating machine is 200 m/min and the paper web width is 2565 mm. Currently, it is suitable for water-soluble coating of...

English

English English

English Español

Español Português

Português Русский

Русский