- Pulp Machine

- Paper Coater

- Drying Equipment

- Yankee Hoods

- Hot Air Drying Cabinet

- Air Diverter

- Through Air Dryer (TAD System)

- Paper Machine Hood

- Auxiliary System

- Dust Removal Equipment

- PPCS Pulse Jet Baghouse Dust Collector

- XD Multi-Cyclone Dust Collector

- Wet Dust Collectort

- Combined Electrostatic Precipitatort

- Noise Control Equipment

- Heat Recovery Device

- Centrifugal Fan

- Axial Flow Fan

- Papermaking Workshop Ventilation Equipment

- Air Supply System

- Turnkey Projects

- Pulp Drying Machine and Drying System

- Tissue Paper Making Machine

- Specialty Paper Machine

Pulp Drying Machine and Drying System

Description

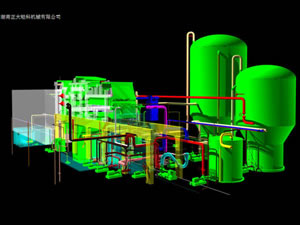

Zhengda Qingke Hi-tech Machinery Co., Ltd. is capable of providing customers worldwide with turn-key project services of pulp drying machine and drying system. These services include consultation, designing, management, installation and commissioning.

Advantages of Pulp Drying Machine and Drying System

1. The length of drying section can be shortened by more than 50%, which greatly saves constuction costs.

2. Pulp drying machine can easily regulate horizontal moisture difference to obtain pulp boards of more homogeneous moisture.

3. Pulp boards are affected by less tensile force in the drying section so that they can move more smoothly, resulting in less broken paper.

Components of Pulp Drying Machine and Drying System

1.Twin Wire Forming Section

This part is made up of hydraulic headbox, closed dehydration system, dehydration tank, wire stretcher, wire rectifier and cleaning device.

2. Press Section

Press section includes a set of vacuum preloading, a set of vacuum pressing and a set of high impulse pressing. This pressing structure can ensure that pulp boards get effective dehydration in this section.

3. Dryer Section

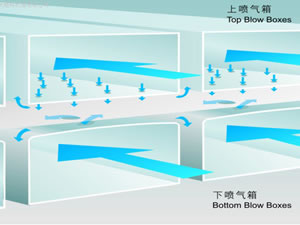

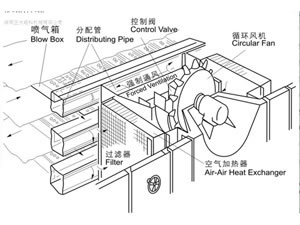

The dryer adopts multi-layer arrangement and bases on airflotation non-contact drying principle to dry pulp boards. Paper web moves through jet cases which provide hot air as energy and heat to dry paper web. The upper and lower jet cases can be separated by air cylinder for cleaning and threading.

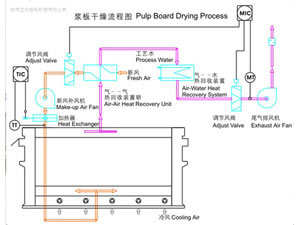

Hot Air Circulation Process

1. To make most use of heat, the outer circulation system of dryer has two-stage heat recovery devices. The first one is gas-gas heat recovery device which employs hot and humid air to preheat fresh air. The fresh air then is heated in the heater and later sent to the bottom of dryer.

2. The second stage is gas-water heat recovery unit. It makes use of waste heat to warm up process water and heating water.

3. The bottom of dryer is equipped with a set of air supply system that functions to cool dowm pulp boards before they leave the dryer section.

Corollary Equipment and System

1. Twin wire hot air drying pulp machine

2. Steam condensate system

3. Pulp approach flow and purification system

4. Vacuum system

5. Broken paper disposal system

6. Transmission control system

7. DCS and QCS paper machine control system

We are a professional supplier of pulp drying machine and drying system. Founded in 2003, the company has accumulated abundant manufacturing experience. All our products have passed ISO9001 certification, thus trustworthy. All products can be exported to foreign countries, like the United States, Russia, Germany, France, Japan, Brazil, etc. If you are interested in our pulp machine and drying system, please visit our website or contact us directly.

- Tissue Paper Making MachineTo meet the increasing demand of the market, tissue paper making machine is thus designed and manufactured. It is widely appreciated among clients for its durability, reliability, power performance, high strength, sturdy construction and easy operation. Besides, tissue paper machine also enjoys low maintenance and high dimensional accuracy. Moreover, tissue paper making machine...

English

English English

English Español

Español Português

Português Русский

Русский