- Pulp Machine

- Paper Coater

- Drying Equipment

- Yankee Hoods

- Hot Air Drying Cabinet

- Air Diverter

- Through Air Dryer (TAD System)

- Paper Machine Hood

- Auxiliary System

- Dust Removal Equipment

- PPCS Pulse Jet Baghouse Dust Collector

- XD Multi-Cyclone Dust Collector

- Wet Dust Collectort

- Combined Electrostatic Precipitatort

- Noise Control Equipment

- Heat Recovery Device

- Centrifugal Fan

- Axial Flow Fan

- Papermaking Workshop Ventilation Equipment

- Air Supply System

- Turnkey Projects

- Pulp Drying Machine and Drying System

- Tissue Paper Making Machine

- Specialty Paper Machine

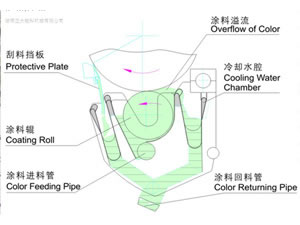

Paper Coater

Introduction

Paper coating machine is generally applied to the production of BOPP (Biaxially-oriented Polyropylene) packaging tapes. This paper coater uses a high-speed coating head which can effectively reduce bubbles. Currently, it is suitable for water-soluble coating of all kinds of paper.

Classification

Paper coating machine can be subdivided into brush type, air knife type and blade type. The blade coater mainly includes coater framework, backing roll, coaitng roll, coating pan, blade metering device, bow curved roll, space limit adjusting device, backing roll sprayer, deckle, pneumatic control system, etc.

Its operating speed of scraper coating machine is 200 m/min and the paper web width is 2565 mm.

Advantages

1.The hot air drying system of paper coating machine has two drying methods. One is single side hot air drying, applicable to paper drying. The other is two-sided flotation hot air drying that is suitable for drying tissue paper, such as art paper, writing paper, etc.

2. The blade coater adopts scraper metering device and the feeding device uses roller feeding, leading to a good circulation of coating.

3. Pneumatic control system utilizes PLC control operation. Therefore, paper coating machine is featured by simple operation, safety, reliability and convenient maintenance.

4. Paper coater has a good coating effect. After being coated, the paper sheets and paperboards have optimal smoothness and glossiness.

Performance

1. Paper coating machine is able to further improve paper quality, for it thoroughly solves the problem that wet paper sheets stick to the paper guide roll.

2. High-precision tension control ensures stable and reliable tension, improving running performance of scraper coating machine. It also ensures high coating evenness.

3. Inductive vector control is equipped on the paper coating machine to achieve constant tension in the process of acceleration and deceleration. Thus, mechanical cost is lowered.

Parameters

1. 3400 to 6000 mm Blade Paper Coating Machine

| Name | Scraper Coating Machine |

| Diameter of Backing Roll (With SKF or NSK Bearing) (mm) | 800-1000 |

| Diameter of Feeding Roll (With SKF or NSK Bearing) (mm) | 350-450 |

| Max. Web Width (mm) | 6000 |

| Max. Operating Speed (m/min.) | 1000 |

| Coating Weight (g/m2) | 5-15 |

| Coating Solid Content | 58%-65% |

| Metering unit and coating pan are lifted by cylinder. | |

| Feeding device adopts pneumatic lifting or hydraulic lifting. | |

| Name | Blade Coater |

| Diameter of Backing Roll (With SKF or NSK Bearing) (mm) | 600-700 |

| Diameter of Feeding Roll (With SKF or NSK Bearing) (mm) | 320-350 |

| Max. Web Width (mm) | 3200 |

| Max. Operating Speed (m/min.) | 550 |

| Coating Weight (g/m2) | 5-15 |

| Coating Solid Content | 55%-65% |

| Metering device and feeding device adopt pneumatic lifting. | |

| Coating pan is lifted by cylinder. | |

- Drying EquipmentThe drying equipment for paper machine works to remove water from paper stock. It has five types: Yankee hoods, hot air drying box, air diverter, through air dryer and closed hood for paper machine. Nowadays, drying machinery is widely applied in many fields.In the drying process, drying equipment transfers heat and hygroscopic water to ensure that the concentration of...

English

English English

English Español

Español Português

Português Русский

Русский